Operating food extruders involves potential risks that can cause harm to individuals and compromise product quality. By implementing appropriate safety measures, we can minimize these risks and create a safer working environment. Additionally, adherence to safety guidelines enhances operational efficiency and helps maintain the integrity of the final food products. Let's delve into the specific safety measures that should be taken when operating food extruders.

Food extruders are complex machines that require proper handling and care. By following the safety measures outlined below, operators can minimize the risk of accidents and ensure smooth operation:

Before operating food extruders, it is crucial to provide comprehensive training and education to the operators. This training should cover various aspects, including machine operation, emergency procedures, and safety protocols. Operators should be well-versed in the machine's functionality, potential hazards, and how to respond effectively to any unforeseen circumstances.

When operating food extruder machine, operators should wear the appropriate personal protective equipment (PPE). This may include safety glasses, gloves, helmets, and non-slip footwear. Wearing PPE shields operators from potential hazards such as flying debris, hot surfaces, and accidental spills, reducing the risk of injuries.

Regular inspection and maintenance of food extruders are essential to identify any mechanical issues or signs of wear and tear. Operators should follow the manufacturer's guidelines for routine maintenance and conduct inspections before and after each operation. Prompt repairs or replacements of faulty components help prevent accidents and ensure optimal performance.

Lockout/tagout procedures are crucial when performing maintenance or cleaning tasks on food extruders. These procedures involve isolating the machine's energy sources and securing them with locks or tags to prevent accidental startup. By strictly adhering to lockout/tagout protocols, operators can protect themselves from unexpected machine activation and associated hazards.

Suggested reading:Before operating a food extruder, it is important to ensure that the machine is correctly set up. This involves aligning the extruder components, verifying the proper installation of screens and dies, and confirming the accuracy of temperature and pressure settings. A well-set machine minimizes the risk of malfunctions and helps maintain product consistency and quality.

Operators should continuously monitor and control critical parameters during the extrusion process. These parameters may include temperature, pressure, and speed. Regular monitoring allows for timely adjustments, ensuring that the extruder operates within the specified limits and maintains product integrity. Automated monitoring systems can also be employed to enhance accuracy and efficiency.

In the event of an emergency ormalfunction, operators must be familiar with the proper shutdown procedures. These procedures should be clearly defined and communicated to all operators. Immediate action should be taken to shut down the machine, isolate it from power sources, and address the emergency situation. Regular drills and training exercises can help ensure that operators are prepared to respond effectively in critical situations.

Maintaining a clean and hygienic environment is essential when operating food extruders. Regular cleaning of the machine and surrounding areas helps prevent the accumulation of debris, contaminants, and bacteria. Operators should follow appropriate sanitation practices and use food-grade cleaning agents. Adhering to hygiene standards ensures the production of safe and high-quality food products.

Operators should be knowledgeable about the proper handling and storage of ingredients and raw materials. This includes understanding the potential allergens present in the production process and implementing appropriate segregation and labeling practices. Following proper handling procedures minimizes the risk of cross-contamination and allergic reactions, safeguarding consumer safety.

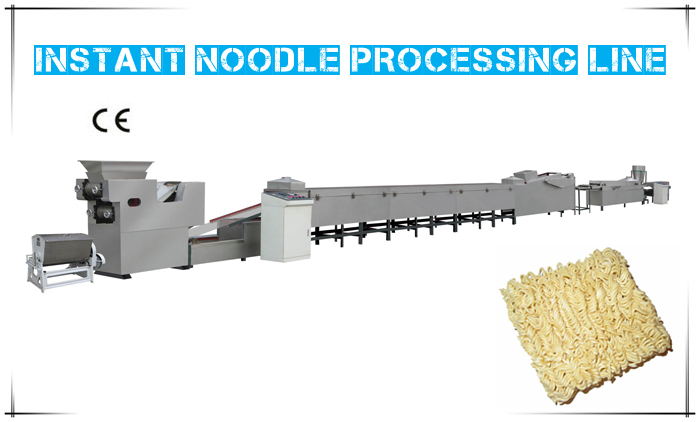

Food extruder Processing Line may produce heat, steam, or fumes during operation. Adequate ventilation is crucial to remove these byproducts and maintain a comfortable and safe working environment. Proper ventilation systems should be in place to control temperature, humidity, and air quality. This helps prevent the buildup of harmful substances and improves the overall working conditions.

Safety should be a top priority when operating food extruders. By implementing the outlined safety measures, operators can minimize the risk of accidents, protect their well-being, and ensure the production of safe and high-quality food products. Thorough training, proper maintenance, and adherence to safety protocols are essential for maintaining a safe and efficient production process. Remember to always prioritize safety when operating food extruders to create a secureand productive working environment.

Suggested reading:Next

Related Articles

Comments

Please Join Us to post.

0